Products

Product Description AKN

AKN THERMAL PLASTIC UTENSISL MFG.CO

AKN-FLEX UNIVERSAL GENERAL CATALOGUE

AKN-FLEX® Universal is Five-Layer artificial casing made of Polyamide, Polyolefin and adhesive (modified Polyethylene) permitted for use in the food industry. All of raw material prepare from well-known and leading polymer and additives producers.

The quality of the raw material used to manufacture the casing is confirmed by UAE health ministry and complies with EC and FDA regulation.

APPLICATION

AKN-FLEX® Universal Casing and intended for production transportation, Storage and sale of:

- Traditional cooked sausage and ham products.

- Paste brown.

- Processed Cheeses, margarines.

- Liver & blood sausage.

- Frozen products such as sausage.

- Ice Cream

- Animal feeds

- Other food products

Advantages Product AKN

High mechanical strength

Caliber stability

High level of Thermo-shrinkage

High Barrier properties

Storage and transportation

Our products are designed to ensure easy transportation and efficient use of storage space. Their compact design and efficient packaging reduce costs and improve overall logistics efficiency.

High level of Thermo-shrinkage

Properties of casing are the best preventer against forming of fat and gel packets as well as wrinkles and they give organoleptic properties to final products.

Caliber stability

Caliber stability of AKN-FLEX® Universal casing is very important during thermal treatment, this property guarantees absence of under cooked or sodden sausage, and provide constant diameter along the whole length of sausage stick allows to plan casing consumption. Stability of caliber gets special actuality when manufacture of portioned sausages with fixed weight.

High mechanical strength

Allows to use AKN-FLEX® Universal with automatic or semi-automatic clipper to ensure stability of the shape and fixed weight.

High Barrier properties

Permeability of AKN-FLEX® Universal casing for oxygen and water vapor is very low and ensured by a carefully selection of type and combination of Polymers , which provide.

- Minimal (Zero) losses weight during thermal treatment and storage of meat and sausage products.

- Microbiological stability of products during storage.

- Prolonged shelf life of sausage

- Excellent selling appearance of the finished products.(without any wrinkles)during storage.

- Natural color meat product stability is very good during storage and casing of this is low oxygen penetration and low oxidation of fat and oil.

STORAGE AND TRANSPORTATION

AKN-FLEX® Universal Casing should be in original packing on racks or pallet in dry, clean warehouse without foreign smell and direct sun light in cool to normal temperature (5-35°C) and relative humidity less than 80% and not closer than one meter to heating devices.

- If the casing was stored at a temperature below 0°C then before use should be hold it at room temperature (more than 5°C)at least 24hr.

- It is recommended to open the original packing just immediately before use of the casing.

- When stacking the rolls of casing, it is required to use separator between faces of rolls.

- The rolls should be unwounded carefully in vertical position in order to prevent scratching of folded edges of casing and it is necessary to ensure that the shell is not injured.

STUFFING / CLIPPING

It is recommended to over stuff AKN-FLEX® Universal casing for 6-10% bigger than nominal diameter (nominal diameter means before soaking) in order casing shows its best properties.

For example, recommended stuffing diameter for casing of caliber 50mm is 53-55 mm overstuffing more than recommended diameter may cause to casing rapture while boiling or cutting of final product. Never puncture casing itself because will rapture, if punctured.

AKN-FLEX® Universal Casing can be stuffed and clipping on automatic or semi-automatic, but they can also be manually tied.

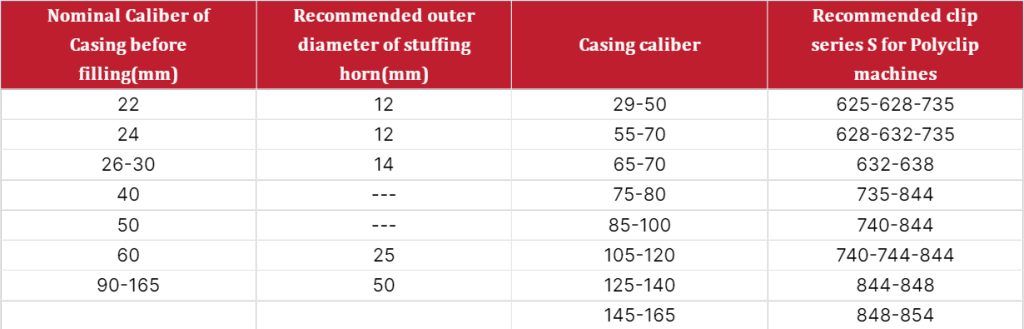

When using shirred casing make sure that the stuffing horn diameter is suitable for the inner diameter of the shirred stick. The stick must freely fit the stuffing horn and the difference between the inner diameter of the stick and the outer diameter of the horn must be as small as possible.

The clip must be fastened very tightly in order to prevent their slipping without damaging the casing.

This table is only rough information. In order to determine whether the clip match with caliber of casing, see recommendation of the manufacturer and the technical description of clipper & clipping machine.

PREPARATION OF CASING FOR USE

- In order to provide good elasticity while stuffing of AKN-FLEX® Universal and perfect the casing must be soaked in potable water at a temperature of 18-25°C.

- Casing in reel form before stuffing should be cut on pieces and soaked in water not less than 30 minutes.

- Shirred casing is to be soaked in water without net removal not less than 1 hour.

- Unused soaked casing is to be drowning from water, drain the excessive water and leave the wet casing away from any sources of heat for using on next delay/day, casing should soak again before filling.

- It is forbidden to soak the casing in hot water, because this may start a process of uncontrolled longitudinal and transvers shrinkage leading to reduction of the length and caliber of the casing.

COOKING

Cooking conditions

Time completely depends to cooking room and type of it. Some cooking room has leakage of steam or not very good in isolation.

But with all cooking room AKN-FLEX® Universal can use: For a rule of thumb cooking with steam (80°C) or boiling water (72-78°C) when temperature of core of good reach to 72 °C or more, cooking is complete.

In our experience for example for caliber of 60 mm need a time about 2 hours for a cooking by steam and with about each increase/decrease 30mm in caliber time increase/decrease 1 hours.

COOLING

After thermal treatment sausages should be immediately cooled with spraying of cold water until getting 25-30°C temperature in center of goods.

Important note: Cooling by air can lead to wrinkles forming.

After spraying of cold water sausage must be air dried and then place in refrigerator at 11-6°C until delivery to a customer.